Since the 19th century, microfiltration has been developed as a membrane filtration technology for treating different effluents and wastewaters (Eykamp, 1995). But why is this separation process so widely used, and what types of contaminants can be removed using microfiltration technology?

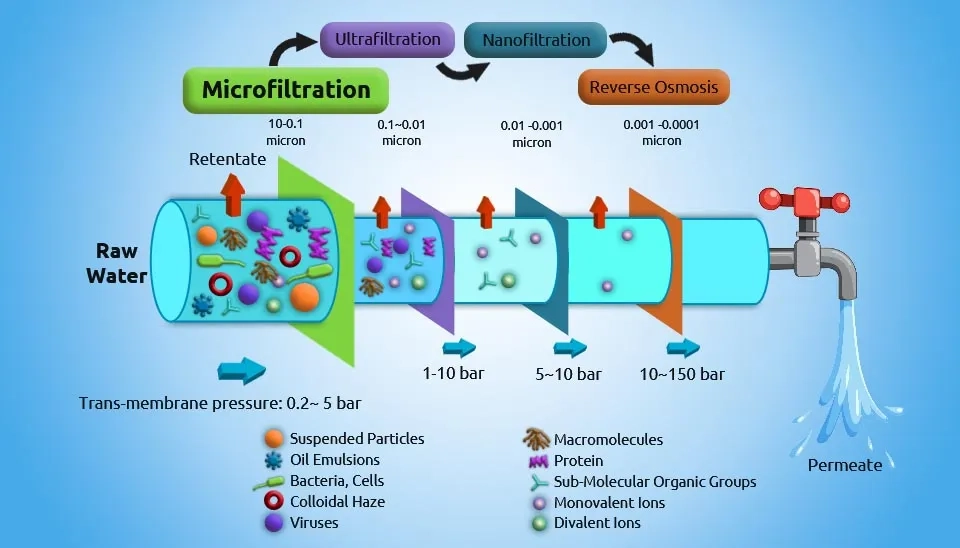

The MicroFiltration (MF) technology uses the physical separation principle to remove micrometer-sized substances, like suspended particles, large bacteria, major pathogens, proteins, and yeast cells (Grant, 1989; Baker, 2012). Coarse filtration membranes are highly versatile and efficient in filtering a broad range of large-molecule pollutants, making them ideal for pretreatment processes in wastewater treatment. Due to the pore size of membrane separation layer, typically between 0.1 and 1 μm, this technology remains a preferred choice for the initial stages of filtration in water purification (Anis et al., 2019).

Microfiltration Applications | Microfiltration Advantages |

|---|---|

Water and wastewater treatment plants Food and beverage industries Pharmaceutical industry Desalination industry Drinking water production | Big economical saving Reduce the overall water production costs Improving permeable qualities Better water and wastewater treatment Do not change the pH or temperature of the solution Improves the product quality There is no need to add chemicals in the process Highly permeable Have a uniform surfaced Easy to operate and scale up No large amount of space is needed |

Although microfiltration offers several advantages and is commonly used in applications such as food and beverage, pharmaceutical, semiconductor industry, and desalination processes, membrane fouling is known to be one of the main problems of this technology (Yalcinkaya et al., 2020). However, with the implementation of anti-fouling strategies and advanced membrane cleaning techniques, the performance of microfiltration systems can be significantly improved, paving the way for broader applications in the future.

1. Microfiltration Technology

Membrane technologies have evolved significantly over the last few years. The membrane processes are considered necessary for chemical and biochemical processing due to their availability and economic characteristics, overall membrane flux, low fouling, and low process cost (Singh and Purkait, 2019). Pressure-driven membrane operations are classified into four main processes based on the pore size: (1) Microfiltration (MF) (0.1–1 μm), (2) UltraFiltration (UF) (0.01–0.1 μm), (3) Nanofiltration (NF) (0.001 to 0.01 μm), and (4) Reverse Osmosis (RO) (0.0001 to 0.001 μm) (Yalcinkaya et al., 2020; Anis et al., 2019).

Membrane-based filtration with micro-scale pores is the most utilized membrane in industrial markets, responsible for about 40% of total sales in Europe and the USA (Huisman, 2000). This low-pressure membrane process can be used in a number of sectors in different areas, including wastewater reclamation, the food industry, pharmaceuticals, desalination, and biotechnology, due to its wide range of pore sizes.

Over the last decade, porous membrane research has gained great importance. This article aims to review the materials used in micro-pore membranes, the two main modes, advantages, and disadvantages of this technology. Potential applications that effectively use this filtration method are also discussed.

Table. Membrane-based separation process characteristics

Pore Size | Method | Material retained | Material passed |

|---|---|---|---|

0.1- 1.0 μm | Molecular sieve | Suspended particles, bacteria | Water, dissolved solutes |

2. Microfiltration Operation Modes

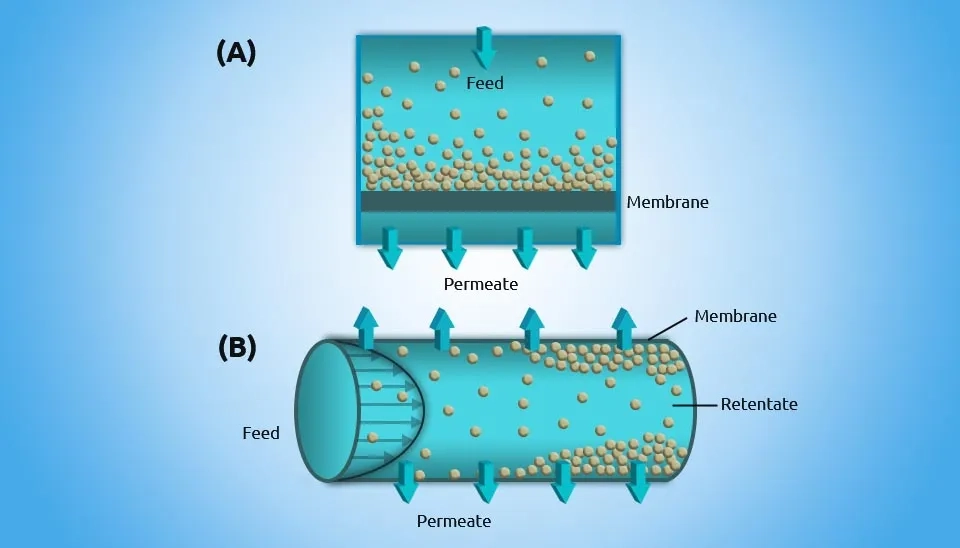

Micron-scale membrane filtration can be carried out in two operation modes: (1) dead-end filtration and (2) cross-flow filtration. Both are very important and are used around the world. The dead-end filtration can be used in batch configuration, and the cross-flow is usually used in continuous mode. Dead-end filtration is suitable for laboratory-scale processes, whereas cross-flow is commonly used on an industrial scale.

The selection of a proper mode is based on the advantages and disadvantages of each operation mode, such as scale of operation, low fouling, etc. For example, dead-end filtration provides a high level of recovery as well as fouling. Whereas cross-flow provides less recovery and low fouling, which makes it a better option for large-scale operations. Another advantage of cross-flow filtration is its continuous operation mode and its ability to limit cake-layer formation. Dead-end filtration is more suitable in situations where there is a low level of particle concentration (like in the pharmaceutical industry). Dead-end filtration can also be used in some membrane-based wastewater treatment systems, where backflush techniques and gas sparging are so effective that it won’t be necessary to use cross-flow filtration (Huisman, 2000; Singh and Purkait, 2019).

3. Microfiltration Materials

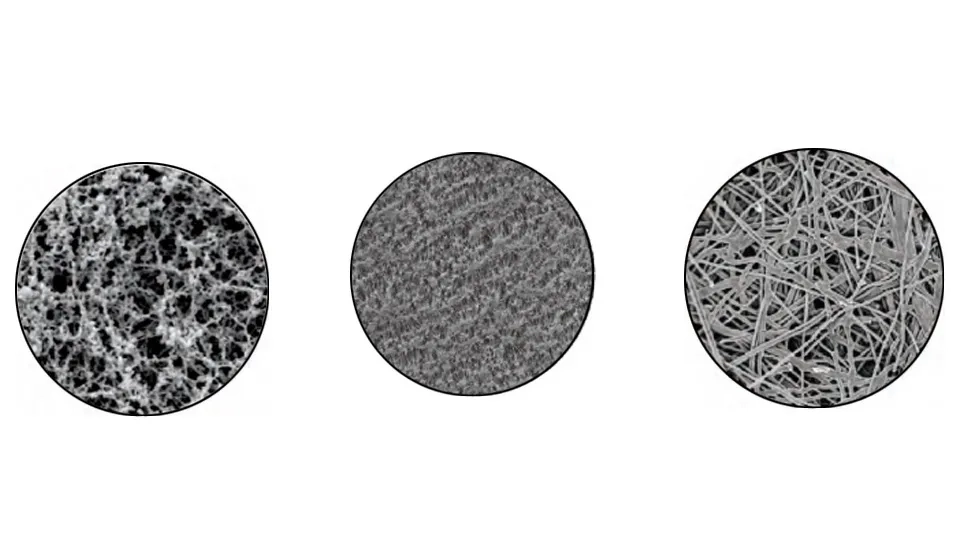

Over the last decade, several microfiltration membrane materials have been found. Low-pressure filtration can be done in several layers with/without fillers, just like NF and RO membranes, consisting of active and support layers forming the membrane structure (Bukhari et al., 2018). Porous membranes can be procured by different polymers, like PolyAmides (PA), Cellulose Acetates (CA), PolyVinyliDene Fluoride (PVDF), PolyTetraFluorethylene (PTFE), Polysulfide (PS), olefins, or PolyCarbonate (PC). Due to some properties like excellent film-forming, good mechanical strength, stability over a wide range of pH levels, etc., these polymers are known as good membrane materials. In addition, due to their excellent chemical, thermal, and mechanical stabilities, microfiltration membranes that are prepared from inorganic materials are more suitable for industrial applications (Gul et al., 2021).

Other microporous membranes are made from glass, metals (such as silver and stainless steel), and ceramics (like alumina, zirconia, and titania). Ceramic membranes are more favorable than polymeric membranes for industrial activities. But their high cost is one of the factors that prevents them from developing. The sintering temperature, preparation process, and materials used are major factors that cause the high cost of ceramic membranes (Huisman, 2000; Singh and Purkait, 2019). Some advantages of ceramic membranes are:

Excellent resistance to high concentration and high temperatures

High thermal stability for industrial emulsions, which contain suspended solids.

Better selectivity and productivity in comparison with polymeric membranes due to their well-defined pore size distribution

Ability to apply membrane cleaning by various chemicals without any adverse impact on membrane performance (Kwaśny et al., 2018; He et al., 2019).

4. Microfiltration Applications

Microfiltration finds potential in several applications. Over the last ten years, there has been a growing trend in wastewater treatment and the food industry, while research for some applications like desalination and medicine has remained almost constant. The most important industrial fine filtration application is water and wastewater treatment, which has dominated the microfiltration market in recent years. The microparticle filtration process is usually carried out in combination with other conventional or membrane-based treatment methods. For example, Changma et al. (2019) have reported an electrocoagulation-microfiltration hybrid system that is used for oily wastewater treatment.

For desalination and industrial wastewater treatment, ceramic fine filtration membranes have shown great efficiency (Mouiya et al., 2019). Ali et al. (2017) also reported the fouling behavior of microfiltration systems for water and wastewater treatment, which needs to be well managed. It is necessary to consider this issue in the food industry, where fine filtration membranes are used on a large scale to remove bacteria from food products.

In many cases, fine filtration is likely to be the most effective solution for the removal of certain bacteria from dairy products (Fauquant et al., 2014). For example, for milk filtration, micron-scale membrane plays a key role in removing spores and bacteria (Fauquant et al., 2014; Griep et al., 2018), retarding the formation of gelatin, and sediment formation in ultra-high temperature milk (D'Incecco et al., 2018). However, further research must be taken into account in this field, where the nutritional value can be protected as well as minimizing costs at the processing stage. This will also result in the development of novel microporous membranes.

The fine filtration technology is being used in the desalination industry as a pretreatment step prior to NF or RO due to its ability to remove a variety of large-scale contaminants (Anis et al., 2019). Since the desalination performance achieves a lower Silt Density Index (SDI) with the utilization of MF, several industrial sectors and pilot plants have been using this technology in recent years. Ebrahim et al. (2001) reported a great improvement in the SDI variation of 0.24-3% by using microfiltration pretreatment. Still, due to the growing trend of other conventional and unconventional pretreatment methods, its research is mainly limited (Anis et al., 2019).

The utilization of microparticle filtration in the pharmaceutical industry is the least studied area of research. While other membrane-based technologies, like ultrafiltration technology, are being more studied since the membrane pore size in UF is more suitable for effective removal of certain contaminants (Aspiyanto et al., 2018).

Another application of microfiltration technology is drinking water production. Although nanofiltration technology and reverse osmosis are predominantly used for producing fresh and potable water from distilled or sea water, micro-pore membranes are found to be suitable to treat wastewater to ultimately achieve safe drinking water (Anis et al., 2019).

5. Microfiltration Advantages and Disadvantages

With continuous growth in microfiltration technology, mainly for seawater pretreatment, a big economic saving would be achieved through controlling the membrane and increasing the membrane’s lifetime. Despite the fact that initial investment costs a lot, it is still possible to reduce overall water production costs by using micron-scale membranes by improving their permeate qualities. A proper microfiltration technology with new and advanced backwashing approaches, as well as controlling membrane fouling and increasing contaminant selectivity, would enhance water and wastewater treatment (Anis et al., 2019).

Micro-separation membranes offer several advantages, including the fact that they do not change the pH or temperature of the solution during the separation process. Microfiltration also lowers production costs and improves product quality since there is no need to add chemicals in the process (Uroševic et al., 2017). In addition, they are highly permeable and have a uniform surface; they are easy to operate; no large amount of space is needed; and they are also easy to scale up.

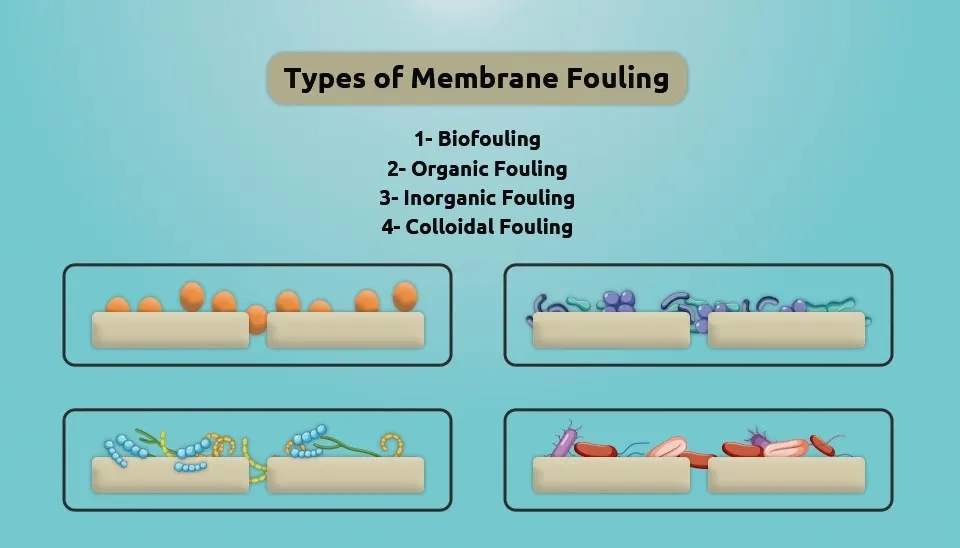

However, the greatest disadvantage of micro-separation membranes is related to their fouling. The foulants can diffuse through the pores and block them, or they can accumulate on the surface and create a cake-layer, which leads to the membrane’s permeability reduction (Gul et al., 2021). Micron-scale membrane fouling will be discussed in the following.

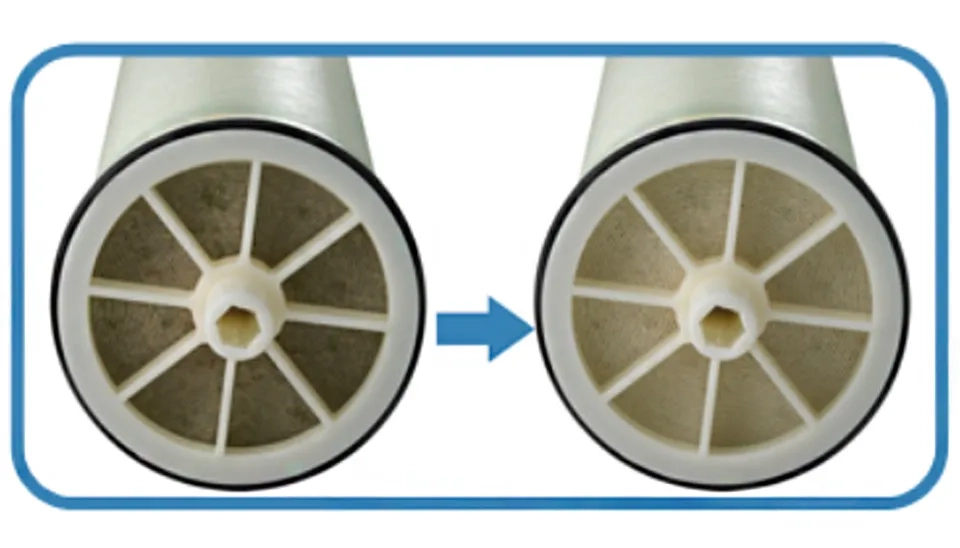

5.1. Microfiltration Membrane Fouling

Membrane fouling is one of the main issues in stages of the fine membrane filtration process (Madaeni et al., 2001). The deposition of organic and inorganic species can block the pores, which leads to the membrane’s selectivity and permeability reduction. This issue will further reduce membrane lifetimes. There are four main types of microfiltration fouling: (1) inorganic fouling/ scaling; (2) colloidal/particle fouling; (3) microbial/biological fouling; and (4) organic fouling (Uroševic et al., 2017; Li et al., 2020).

In wastewater treatment, where several biological contaminants can cause biofouling, microporous membrane fouling is known as a major concern. Therefore, membrane fouling should be studied from a broader perspective and should cover several aspects of membrane modification and fouling causes to ultimately enhance the operation and better understand the fouling mechanisms in microfiltration membranes (Anis et al., 2019).

Since the performance of a microfiltration membrane is highly related to its fouling, scientists have improved some strategies to decrease its adverse impact. Membrane unit cleaning is one of the strategies that has been developed and widely used recently. Maintaining or restoring membrane performance after membrane fouling is the goal of membrane cleaning. However, most of the recent studies on membrane cleaning are mainly focusing on ultrafiltration, and less attention has been paid to microfiltration membrane cleaning (Gul et al., 2021).

6. Future Developments

Since 70 years ago, microfiltration has been developed from a small technology used only in laboratory-scale water treatment to immense industry-scale purification plants. Since the 1980s, it has become possible to use this technology in some new applications, due to the improvement of novel membranes (like ceramics) and technologies (like back pulsing). Nevertheless, there are many challenges that exist, for example, membrane fouling in food and beverage production (e.g., milk and fruit juice), which has a negative impact on the economy of the process. To overcome these issues, scientists and engineers have turned their attention to hybrid and combined processes. Better and more economic separation may be achieved when microfiltration combines with proper pretreatment and post-treatment or with other separation processes. Currently, the most commonly used membranes in most applications are polymeric membranes. However, recent developments have shown that inorganic membranes are more efficient and may broaden the separation spectrum of membranes. But due to their poor mechanical stability and high production costs, the widespread use of inorganic membranes is currently limited. If these limitations are solved in future work, inorganic membranes will offer a high-performance membrane for the next generation (Huisman, 2000).

7. Conclusion

Microfiltration (MF) is a separation process that is commonly used in concentrating, purifying, or removing macromolecular colloids, bacteria, and suspended particles from solutions Microfiltration is one of the most popular technologies for water and primary wastewater treatment and can be used in different applications. They can be made of different materials due to their purpose and have two operation modes: dead-end filtration and cross-flow filtration. Coarse filtration membrane processes have gained importance in separation technologies and provide numerous advantages for various industrial applications, such as having high permeability and being economical, effective, easy to operate, and efficient. Depending on the types, materials, and usage, membranes may lose their efficiency over time. The most significant problem for membranes is fouling or blockage, which can be resolved by cleaning techniques. However, further research needs to be taken into account in this field, and all aspects of this technology should be fully explored.